CHEMOURS TEFLONTM & TEFZELTM

FLUOROPOLYMERS

PLASTICS WITH THE HEART OF A DIAMOND AND THE SKIN OF A RHINOCEROS

This product is available in most of Europe except Italy, Ireland, the UK, and Scandinavia.

MANUFACTURED WITHOUT THE USE OF PFOA

The development of the patented CHEMOURS™ GenXTM technology guarantees the production of high-performance fluorine plastics without the use of perfluoroctane acid (PFOA).

PROPERTIES

- Outstanding chemical resistance

- Resistance against crack formation

- Great temperature resistance

- Anti-stick properties

- Excellent dielectric properties

- Outstanding resistance against weathering and aging

- Toughness and flexibility

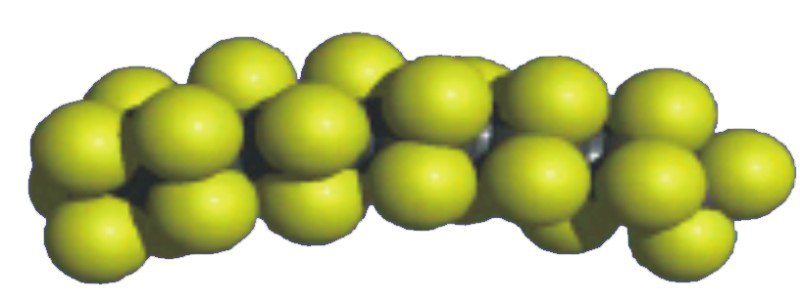

TEFLONTM PTFE - POLYTETRAFLUOROETHYLENE

Classic fluoropolymer PTFE can only be put into the desired form with methods such as pressing, vitrification and mechanical reworking. The evolution of fluoropolymers did justice to this disadvantage. Melt processing was achieved by shortening the main chain and introducing side chains. An example of this is FEP.

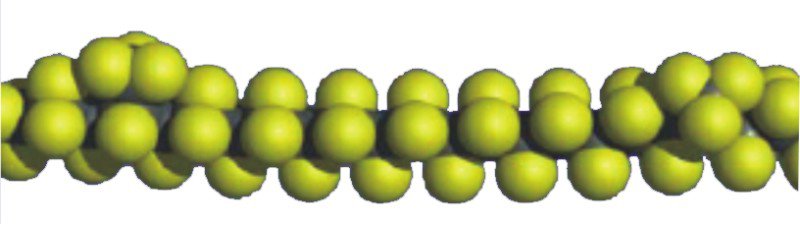

TEFLONTM FEP - FLUOROETHYLENPROPYLENE

FEP is a fully-fluorinated copolymer suitable for permanent use at up to 205°C with the best chemical resistance and dielectric stability. Today, FEP is used frequently in the wire and cable industry via extrusion processes and for transfer pressing for chemical applications. In the injection-molding sector, FEP has had less success due to its relatively large shearing sensitivity.

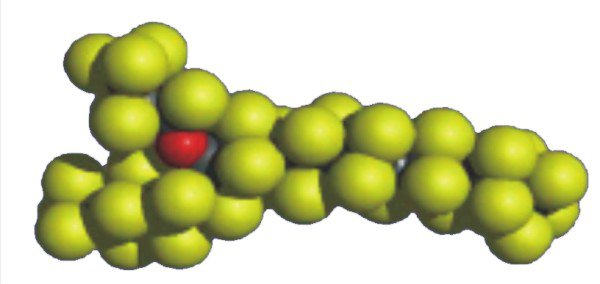

TEFLONTM PFA - PERFLUOROALKOXY

Perfluoralkoxylalkane is a high fluor-containing plastic, a further enhancement of the widespread vitrification material PTFE. In contrast to PTFE, PFA can be processed thermo-plastically. PFA has a low rigidity and hardness, it is resistant to nearly all chemicals, and it demonstrates great temperature stability and is flame-resistant. PFA has a low friction value, it behaves largely inertly, has high sliding abrasion and an extremely low adhesion.

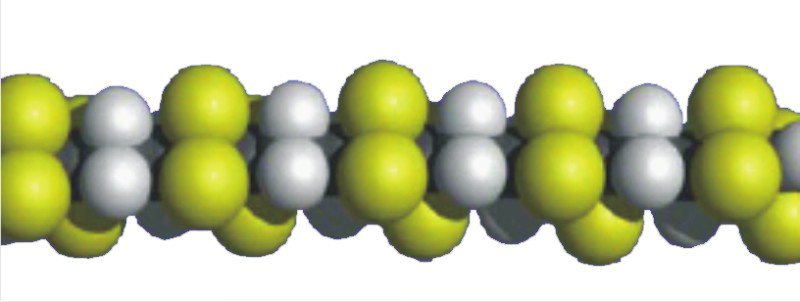

TEFZELTM ETFE - ETHYLENE-TETRAFLUORETHYLENE-COPOLYMER

Ethylene-Tetrafluorethylene is a fluorinated copolymer consisting of the monomers tetrafluorethylene and ethylene. ETFE is a PTFE derivative. Films of this plastic are lightweight and they are very light and UV-permeable. Due to its resistance to many aggressive chemicals (e.g. acids, aromatic hydrocarbons), ETFE also serves as a coating material for chemical devices and containers. Due to its low dielectric constant, it is well-suited as insulation material in electrical technology.

YOUR BENEFITS

There are no REACh problems since all CHEMOURS products are pre-registered. For additional information, consult the CHEMOURS homepage.

WHY DOLDER-BIGLER?

- DOLDER-BIGLER has been a reliable partner in the polymers business since 1957.

- We offer raw material-related technical assistance from well-trained, experienced experts.

- CHEMOURS is available for technical support.

- We also deliver small quantities reliably just-in-time thanks to our warehouses in Basel and Freiburg/Breisgau.

- DOLDER-BIGLER has an international sales and procurement network and is represented in three countries in the heart of Europe.

Let's talk about the varied solutions that CHEMOURS fluoropolymers can offer your company. Give us a call!

Graphics: Wikipedia (public domain)

TEFLONTM and TEFZELTM are registered trademarks of CHEMOURSTM used under license by DOLDER-BIGLER AG.